Vinyl pressing

The pressing plant's heart

We use Toolex Alpha fully automatic devices, some of which are over 40 years old, for pressing. Each machine is unique, but carefully maintained. In order to maintain the functionality of our devices, it is imperative to possess a high level of our technical understanding.

Customizing machine settings for each order necessitates a significant amount of manual labor in the pressing procedure. We conduct a final quality control on both the test pressings and the main pressings, involving visual and acoustic inspections of the records.

We manufacture records from polyvinyl chloride (PVC), both of virgin vinyl or regranulate. Virgin vinyl remains the basic raw material in our production. Regranulate, on the other hand, is made from PVC refuse generated during vinyl production. We can shred surplus records and cut edges and reintegrate them into the production cycle, leading to a significant decrease in plastic waste.

Our extensive experience has demonstrated that the use of regranulate does not lead to any auditory losses. Suitably, we typically employ recycled granulate in our black 140-gram pressings. Upon closer examination, only the record's surface may exhibit minor streaks.

Due to production constraints, we utilize virgin vinyl in both our 7" and 180g presses. Virgin granulate typically composes colored pressings, as it is the only method that ensures colorfastness.

Unparalleled Quality Through Automation

At our vinyl pressing plant, we combine passion for music with the latest in manufacturing technology to deliver premium quality records to discerning audiophiles and music lovers worldwide.

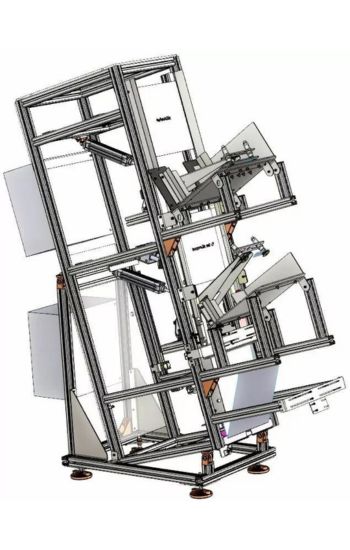

What sets us apart is our commitment to excellence at every stage of production. We're proud to feature a fully automated final packaging process that ensures the highest standards of quality and cleanliness:

We automatically insert our vinyl records into paper sleeves and automatically pack them into hard covers.

This non-stop, automated packaging system guarantees that your vinyl reaches you in pristine condition, untouched by human hands.

By eliminating manual handling, we minimize the risk of contamination, fingerprints, or accidental damage, ensuring that each record maintains its impeccable quality from our press to your turntable.

Experience the difference that meticulous care and advanced technology can make.

Size & weight

We press both 7" and 12" records, and our 7" records are available with both tiny and large center holes.

Are you interested in pressing the 12 inches into either 140g or 180g? We provide both options. We frequently repeat the assertion that a 180g record generally produces a better sound quality than a 140g record.

Nevertheless, the ultimate weight is significantly less significant in the production process than the electroplating and the cut. As a result, it is feasible to generate identical-quality vinyl records for both 140g and 180g.

Therefore, why opt for 180 g? It is all about the tactile experience. A 180-gram record is more durable and comfortable to hold.

Eco record

Our eco vinyl is available as a special pressing. This results in a pressing with distinctive patterns as we employ all color residues.